Applications:

Air Heaters, Heat Pumps, Condensers, Cooling Units, Evaporators, and Chillers.

Advantages

- Fast start-up (due to a pre-configured system)

- Speed continuously controllable

- High operating efficiency due to EC drives

- Constant high degree of efficiency (even under partial load)

- Independent of the supply frequency (50/60Hz), while providing the same level of performance

Features and Construction:

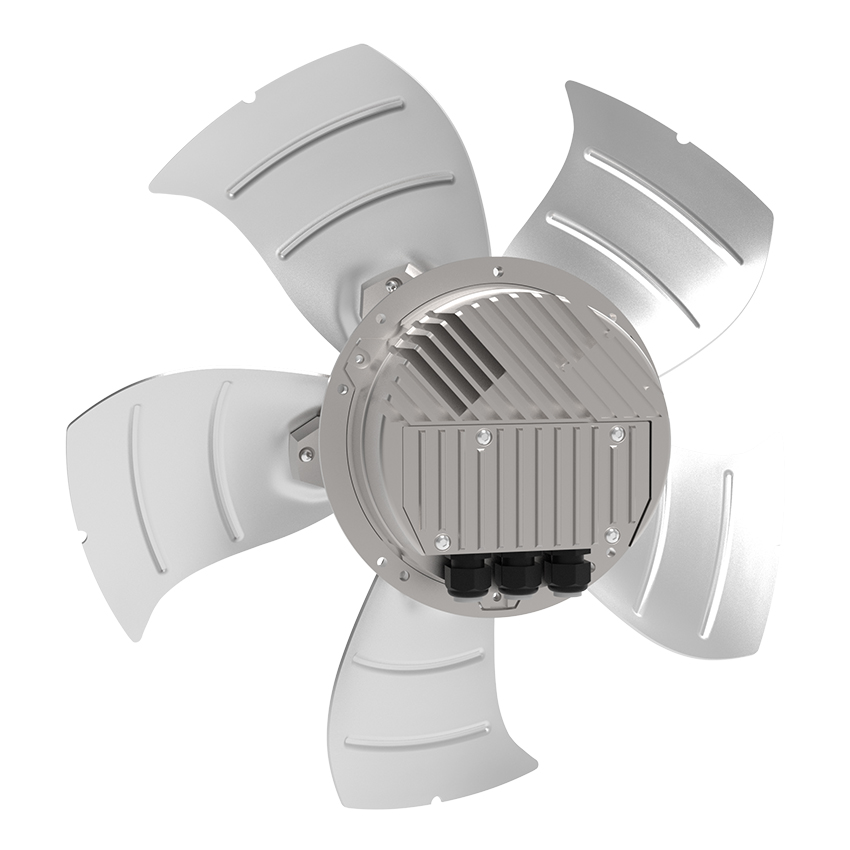

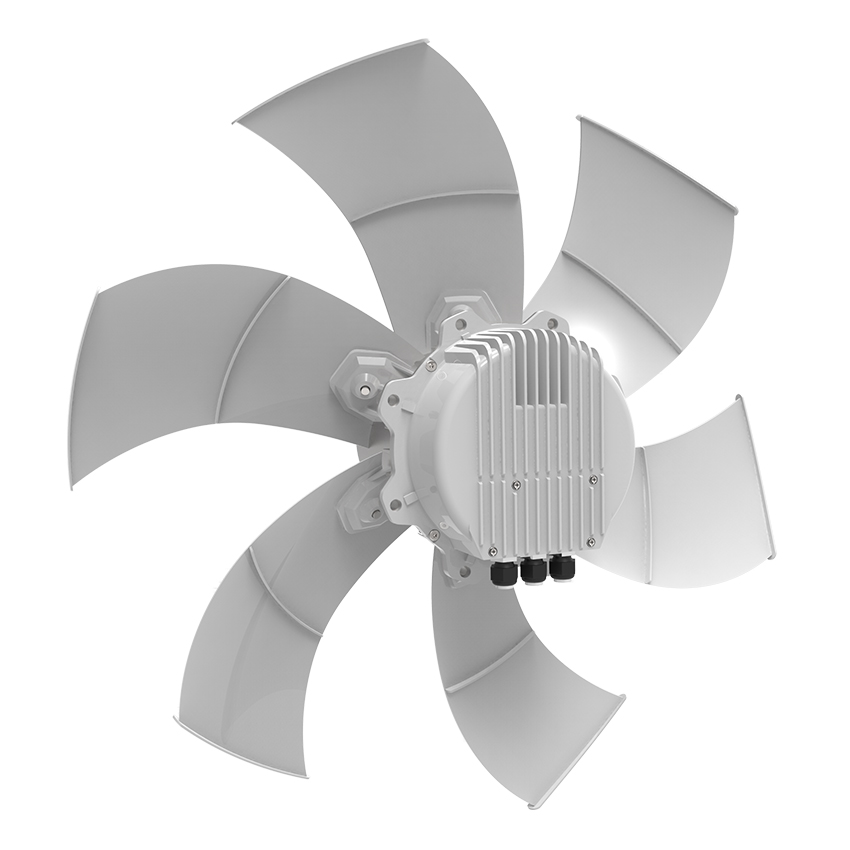

Rosenberg axial fans with improved and noise optimized blades combined with electronically commutated motors (EC Motors or ECM) form a very efficient and design optimized fan unit. Fast startup is ensured because of well-integrated components.

The fans are driven by EC (electronically commutated) motors with sizes G9, V8, GD84, GD112 and GD150 in conjunction with integrated EC-electronics. Custom designed EC motors, flexible production of blades and high-end metal fabrication, gives Rosenberg the capability to manufacture fans that provide the best possible benefit to customers while taking the design demands and the customer’s application into consideration.

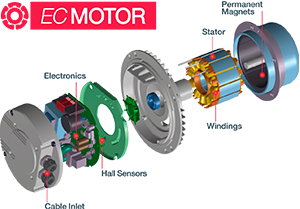

Design and Operation of EC motors

Rosenberg EC-Motors (electronically commutated) are permanently magnetized synchronous motors designed as external rotor motors. A rectifier inside the electronics transforms the alternating current (AC) voltage into direct current (DC) voltage. Depending on the position of the rotor, the EC electronics provide the corresponding motor voltage to the motor (similar to a frequency converter). Differing from a frequency converter, the EC electronics energize the stator phases depending on the rotor position, direction of rotation and the speed requirement (commutation). Permanent magnets inside the rotor create a magnetic field, which is required to generate the torque. This makes it possible to achieve highly efficient, compact, quiet continuous speed control.

Through the use of deep groove ball bearings, closed on both sides, with specially paired grease lubricant, maintenance-free and low-noise operation is guaranteed. The winding insulation corresponds to thermal Class F. Compared to standard EN 60034-30 the Rosenberg EC motor is rated to efficiency class IE4.

Motor and Electronic Protection

The integrated protection mechanisms safeguard the fan from error statuses and overheating. The G9 and V8 signal an error over an open-collector output, the motors GD84, GD112 and GD150 through an alarm relay.

Electrical Connection

The electrical connection can be made at the motor size G9, V8, GD84 and GD112 (1~230V) via lead out connection cable and for the motor size GD112 (3~230V / 3~400V) and GD150 directly via cable gland at the integrated terminal box of the motor.

The supply voltage range, which is designed for 50 and 60 Hz networks, allows for a wide range of applications. The fans are designed for use on symmetric and neutral point grounded systems (TN-S, TN-C, TN-CS, TN networks). Other power supply networks have to be checked for specific projects.

In this catalog, all fans are shown in open-loop control. In open-loop control, the fan speed can be controlled continuously by a preselected target value. Depending on the specific type the preselected target value can be defined by a 0-10 V signal, a PWM signal or Modbus RTU telegrams. Additional information can be found in wiring diagrams from page 32.

In closed-loop control, the EC fan compares the set point to the actual value and adjusts the speed independently within its possible speed range. This means if, e.g., a 3V signal is connected to Analog1, the fan increases its speed up to 3V on Analog2 to match it.

The change of operating mode, reconfiguring the analog input characteristics or reducing the nominal speed can be done by the software program ECParam, or can also be ordered individually for specific projects.

Reference to Directives

Rosenberg Axial Fans with EC motors meet in their design the EMV-Directive EMV 2014/30/EU, Low Voltage Directive 2014/35/EU, and ErP Directive 2009/125/EC.

UL Component Recognition

The motor sizes G9, GD84, GD112, GD150, which are used in the fan types, are UL / CSA recognized. These types are marked on the respective pages with the “Recognized Component Mark”. Additional products have to be checked for specific projects.

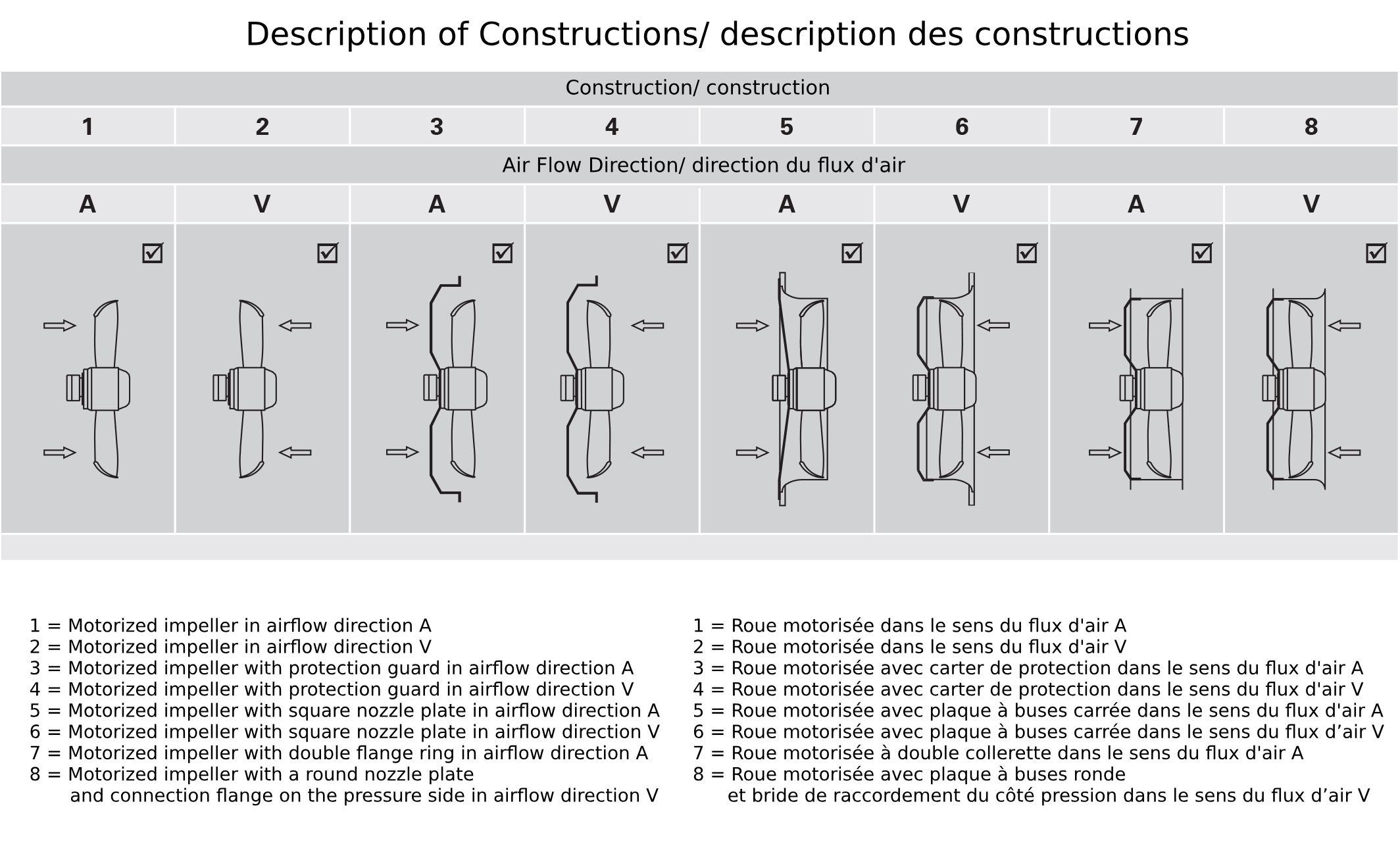

Description of Constructions