Free blowing fans with EC external rotor motor and integrated power electronics

Features and Construction

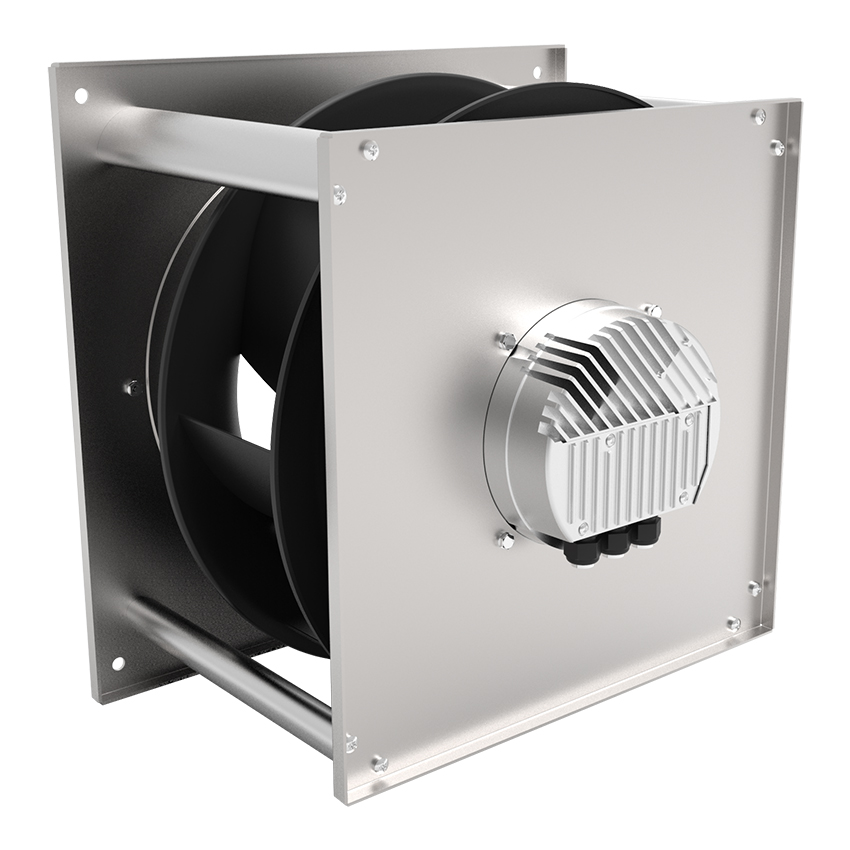

Rosenberg radial fans of the ranges GKHR and GKHM with free running impeller are very compact units.

With regard to the air movement, the fans have an optimum design.

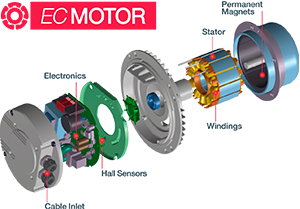

They combine an electronically commutated external rotor motor with a newly designed integrated power electronics.

Using this design concept for the drive, a very compact unit was realized in which the controller and the motor are not divided anymore.

Both power supply and control leads are connected directly to the motor.

The combination of the integrated power electronics motor, together with the flexible production of impellers and efficient sheet metal handling makes it possible to manufacture fan modules for various applications. Constructive demands of the customer can be met.

The fan modules can be provided as:

GKHR: Motorized impeller (mounted and balanced) with or without inlet cone (loose)

GKHM: Fan module

GKHS: Fan module, known as “Spider” construction

GKHB: Fan module with a mounting stand

Advantages

- Easy to install due to the installation of the complete fan module

- Easy maintenance as the fans are not belt driven

- Hygienic, easy to clean

- Compact, space-saving ventilation units as a result of external rotor motor and the high performance backward curved impeller

- Easy determination of the airflow due to measuring device

- Technical decoupling of vibration at the module possible without a problem

- Customers specific variations possible without a problem.

- High economic efficiency as a result of the optimized efficiency of the impeller

- Can be mounted together as a fan array, forming an energy-efficient multi-fan AHU. Learn more about Rosenberg's ECFanGrid.

Design and operation

Due to the external rotor design, the EC motor with its compact design and high power density is particularly predestined for use in ventilation and air conditioning applications. The EC-Motor combines the maintenance-free operation of asynchronous machines with the efficiency control advantages of a direct current motor, especially at low speeds.

- Major efficiency advantages during operation in all situations.

- The motor construction size can be reduced as a result of the EC-Motors high performance. Hereby minimizing the losses as a result of motor blockage with direct driven fans.

- Less additional heat generation. Herby reducing the required cooling performance of the air handling unit.

- The maximum speed is independent of the power frequency.

- The construction of the external rotor motor remains compact.

Electrical Connection

Both power supply and control leads are connected directly at the motor.

Thus, no shielded cable needs to be used.

Speed control

The motor can be speed-controlled steplessly, by using an external potentiometer (accessory) or by an external 0-10 V/ PWM signal.

Performance curve - note

The efficiencies and power consumptions mentioned always relate to the complete system including all losses caused by the impeller motor and the commutation unit.

Air temperature

The fans of the GKH_ range are suitable for air and other non-aggressive gases or steams. The maximum temperature of the medium is 40°C. The increase of air

temperature of the fan and surrounding temperature of electronics is possible by reducing rotation speed.

Contact us for more details.

Description of Constructions