Rosenberg: Leading the way with energy-efficient EC Technology

Our energy-saving EC motors are developed and manufactured exclusively on our modern production line at our headquarters in Künzelsau. Through the combination of know-how and innovative manufacturing technology we attain a quality that meets the highest standards.

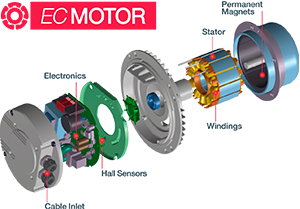

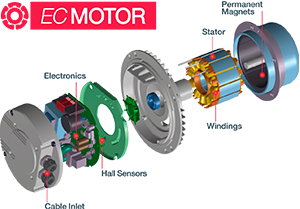

EC (Electronically Commuted, or Electronically Controlled) motors are electric motors which have permanent magnets on the rotor and use electronics to control the voltage and current applied to the motor.

EC motors have no brushes, so avoid the sparking and short life of brushed motors. Because they have electronics controlling the stator, and do not need to waste power inducing the rotor field, they give better performance and controllability, and run cooler than induction motors (for small motors, at least: high horsepower 3 phase induction motors can be very efficient). EC motors are used today in many fractional-horsepower applications where high motor efficiency, reliability, and/or controllability is desired.

Advantages:

EC motors are very high efficiency, and maintain a high efficiency level at part speed. This means that in most cases they use from less than one third to one half of the electricity used by the traditional "shaded pole" induction motors used in the ventilation and refrigeration industries, which in turn translates into lower operating costs and short payback periods.

EC motors’ high efficiency also means that the motors run “cool”, and dramatically reduce the amount of waste heat produced. Reduced waste heat at the evaporator motor level also typically results in reduced operation at the compressor level, which allows further energy savings. Further, running cooler improves the life of highly loaded motor parts like windings and bearings.

EC motors also have a wider operating range than traditional induction motors, which means that one ECM motor can replace a number of induction motor models. In this way, the number of models required by a typical customer is significantly decreased, which decreases and simplifies inventory. This is the main reason why ECM product lines usually include less motor models than their induction counterparts.

In terms of speed control and features, because the motor’s operation is controlled by software, EC motors allow customers to optimize and integrate the motor, fan and controller with the application, and to include features like data communications, constant volume control, variable speed, etc.

EC motors are also quieter than traditional inefficient motors, have longer design life and require less maintenance.

Quality pays for itself. The slightly higher investment costs compared to conventional motors is usually amortized within a short operating time due to lower energy consumption und greater ease of installation. No transformer controller, motor overload switch, thermocouple meter, VFD, or phase angle controller are necessary.